Power generation

During maintenance inspections, nuclear power generating plants rely heavily on rigorous non-destructive testing regimes. SG NDT designs and supplies advanced electroniucs, probes and accesories tailored for the nuclear sector, primarily used in France and Asia for tube, corrosion and welding inspections.

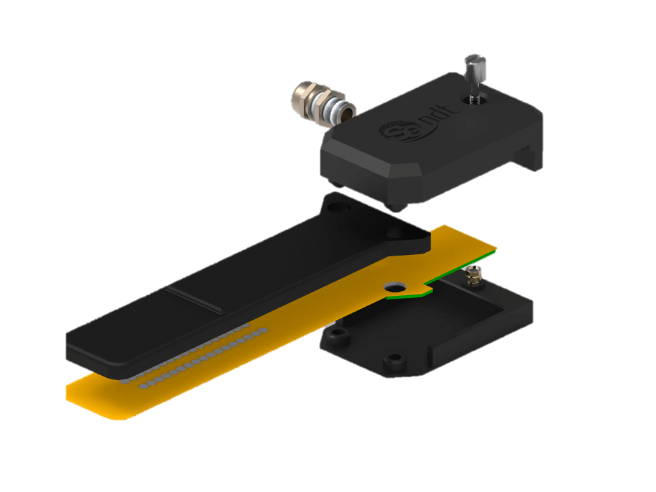

Our innovative ARRAY technology can detect defects in a wide range of complex shapes, reducing inspection time and simplifying data analysis compared to conventional equipment. Turbine inspections, which require superior performance, are perfectly supported by our S2G2, S2G2-WS, and μS2G2-ARRAY systems.

Aerospace

SG NDT technology is an invaluable tool for crack detection inspections and corrosion detection in the aerospace industry. Given that corrosion can be a major concern in aircraft, particularly in an aging fleet, our tools are designed to deliver precise results. They efficiently manage technical complexities, enabling fast and thorough inspections of extensive surfaces in a fraction of the time.

Our instruments’ multiplexing functionality supports up to 512 eddy current coils, making them ideal for inspecting large or complex surfaces, such as turbine blades.

Industrial manufacturing

Bar, tubes, and other steel products

Our ARRAY probes are highly adaptable and often custom-built for inspecting square or hexagonal bars. In addition, both our hardware and software are tailored to meet the specific needs of the industry, offering exceptional flexibility across various applications.

Automobiles

Laser welding on steel plates is one of the key applications of the ECT ARRAY technique. This innovative technology provides a wide range of solutions for automotive manufacturing.

Oil and gas

Heat exchangers in the oil and gas industry require regular and repeated inspection using various electromagnetic techniques, including Remote Field (RFT), Near Field (NFT), Eddy Current (ECT), and more. These methods deliver highly reliable and very rapid inspection results across all tube materials.

Our multi-technology equipment, which supports ECT, RFT and NFT, offers exceptional overall performance unmatched in the industry. The ability to operate in ARRAY mode is a standout feature, particularly for pipeline inspections.

Eddy Current ARRAY technology is also qualified for weld inspections, providing an effective alternative to standard ECT techniques. Eddy Current Array is also being used as an alternative to more conventional inspection methods such as Magnetic Particle inspection and Liquid Penetrant inspection as it gives recordable, traceable, reliable results.

Universities, research centers and laboratories

SG NDT is actively involved in research, feasibility studies, and analysis of existing NDT structures.

Our team of experts works closely with researchers to develop new inspection protocols tailored to specific needs.

Our OEM product line helps reduce equipment costs while providing powerful Eddy Current instruments to laboratories. Additionally, our flexible solutions offer engineers full access to equipment functions through an API interface, enabling seamless integration and customization.