Power Requirements

110V-220VAC, 50-60Hz (Auto voltage sensing)

Operating Voltage

12-15 VDC Power

Environmental

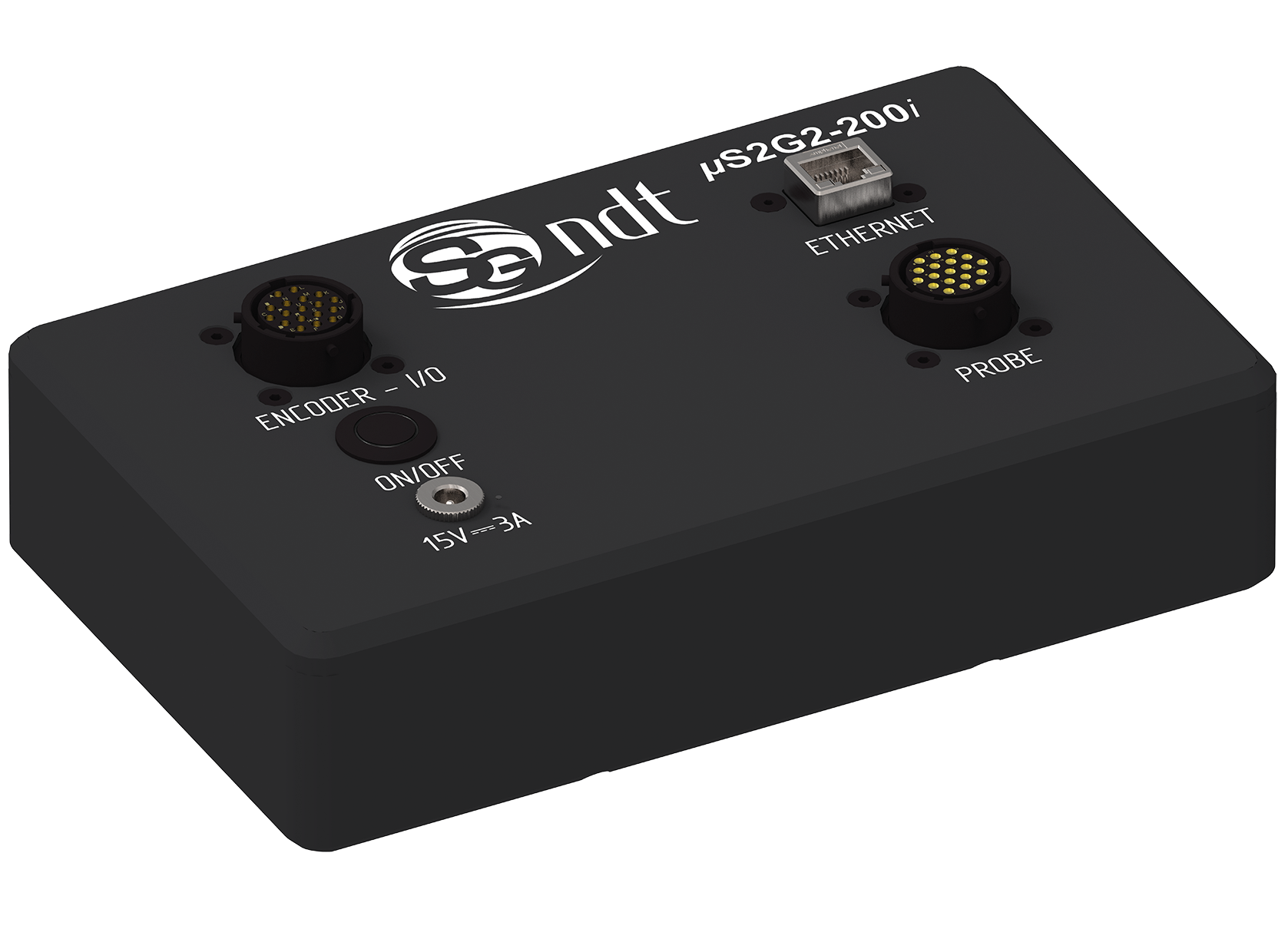

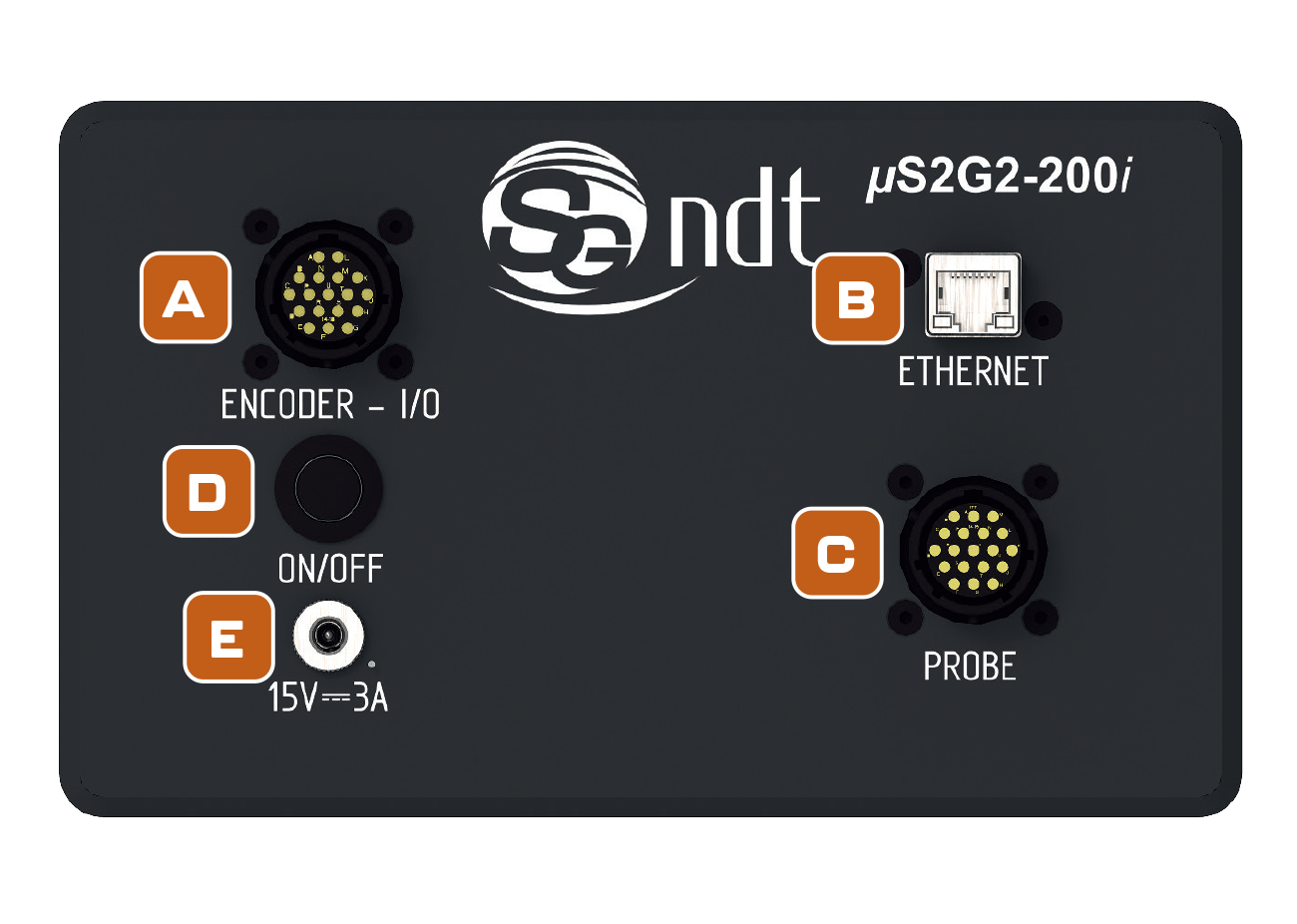

Sealed enclosure, designed for IP65

Size (external dimensions)

20.2cm x 12.2cm x 4.8cm (7.9” x 4.8” x 1.9”)

Weight (excl.batteries)

1.5 Kg (3.3lb)

Computer Interface

Gigabit Ethernet-1000 BASE-T

Compliance Standards

CE, RoHS

Operating Temperature

0°C to 50°C (32°F to 122°F)

Inputs/Outputs

-

RJ45 Ethernet

-

19-pin Amphenol – Extended ECT Connector

-

18-pin I/O Connector

-

12-15VDC Power Input

Encoders

2 quadrature encoder inputs

Remote Controls

- Start/Stop

- Balance

- Status

Alarms

2 independent real-time alarms